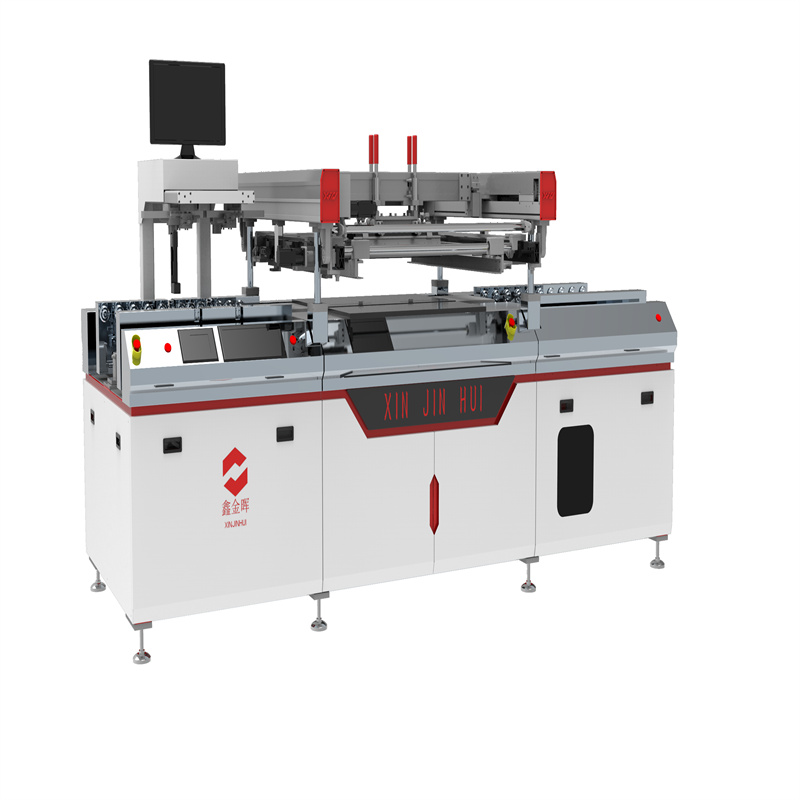

Umshini wokuphrinta wesikrini sikasilika ohlakaniphile

Iphrinta yemaski ye-PCB solder, iphrinta yezinganekwane ze-pcb, ukuphrinta kwesikrini sikasilika wengilazi, ukuphrinta kwesikrini sikasilika welanga, i-pvc, ikhava ye-movbile nokunye.

Wonke umshini wakhiwe ingxenye yokuqondanisa ye-CCD ehlakaniphe ngokugcwele, ingxenye yokunyathelisa kanye nengxenye yokubuyisela impahla, netafula le-shuttle kwesokunxele nesokudla phakathi ukuze uhambise izingxenye eziphrintiwe ochungechungeni.Ifanele imaski ye-solder/ukuphrinta uyinki wezinhlamvu.

1,Ukubekwa kokuphakelayo kusebenzisa isistimu yokufanisa ipuleti elizenzakalelayo le-servo eligcwele, futhi ukunemba kokuma kufinyelela kuzinga lom.

2, I-Servo motor drives printing kanye ne-pneumatic off screen ukuze ibone ukusebenza kwesikrini okuvumelanayo futhi kuvimbele ngempumelelo ukunamathela kwesikrini.I-servo motor ishayela ucezu lokuphrinta ukuze luhambe ngokushesha nangokushelela ukuze kuqinisekiswe ukuma okunembile kwesiqeshana sokuphrinta.

I-3, i-Servo motor kanye ne-precision guide guide yesitimela iqinisekisa ukuma okunembile nempilo ende yesevisi.Isakhiwo sokuphakamisa esiqondile esivundlile sohlaka lokuphrinta siqinisekisa ukuthi ukucindezela kwe-scraper kuyalingana.

4,i-smart interface touch operation, kulula ukusetha, nokutholwa kwamaphutha okuzenzakalelayo kanye nesibonisi sokuxazulula inkinga.Ingcindezi yokuphrinta kanye nepuleti yesikrini ingalungiswa ngokufanele futhi ngokunembile, futhi i-angle ye-scraper ingalungiswa ngokuthanda.

I-5, uhlelo lokuqondanisa okuzenzakalelayo kwesithombe se-CCD, oluhlanganiswe nezinkundla ezisebenza kwesokunxele nakwesokudla, lunika amandla ukusebenza okusheshayo nokunemba okuphezulu kokuqondanisa.Ukucutshungulwa kwenani eliningi lesistimu yesithombe akunqunyelwe yinoma iyiphi ihluzo, futhi noma yiziphi ihluzo zingasetshenziswa njengethagethi.

6, Isigaba sokukhipha

Ingxenye yokukhipha ifakelwe amarola akhiphayo ukuze athathe i-treadmill ayilethe ku-base plate, bese eyibuyisela ku-conveyor.

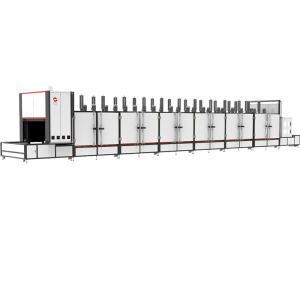

Umklamo ongenhla usekelwe kumqondo "wokusebenza kokuxhuma okuhlakaniphile", futhi ngamaconveyor avundlile engxenyeni yangaphambili nangemuva, amandla okufakwayo angancishiswa kakhulu futhi umthamo wokukhiqiza ungandiswa.

I-PLC: I-Mitsubishi

Umzila wesitimela:THK

Isilinda:I-AIRTAC

Ukuxhumana:I-Mitsubishi

Isikrini sokuthinta:weinview

Ibhande le-synchronous:I-MEGADYNE

I-Bearing:I-NSK

Isikulufu sebhola:I-TBI

Ubukhulu bosayizi wokucubungula:630mm×730mm

Ilensi yokuqondanisa ye-CCD:4

Usayizi omncane wokucubungula:350mm

× 400mm

Ukulungiswa kwe-CCD:130

Ibanga lokuqina kwebhodi:0.8

-4.0 mm

Ukulungiswa kwe-CCD:12 um

Isivinini sokuphrinta:30~300 mm/sec elungisekayo

Ibanga lokusebenza le-CCD:300-720mm

Umkhawulo kasayizi wozimele wesikrini:1200×1100mm

Inkambu yokubuka ye-CCD ephumelelayo:12*15mm

Ubuncane bosayizi wozimele wesikrini:800×800mm

Usayizi wethagethi yesithombe se-CCD:1-3 mm

I-diameter yembobo yepulaki encane kakhulu:

≤ 0.20mm

Izinhlobo ezitholakalayo ze-CCD okuqondiwe:okungenamkhawulo

Ukunemba kwezinga eliphezulu lethebula:±0.1mm/m2

Ukunemba kwesithombe se-CCD:0.01mm

Ukunemba kwembobo yokuxhuma:±0.02mm

Ukujula kwesithombe se-CCD kwenkambu:0-2 mm

8-point clamping center positioning kanye nokuma kwe-CCD okuzenzakalelayo

Ukufana kwe-Squeegee pressure:≤5kgf

I-engeli yokumboza/yokwesula:

±15°

Ibanga lokuphrinta:0 ~ 10 mm

I-Scratch stroke:i-servo 0~900 mm eguquguqukayo

Ukucaciswa okuvela ebhodini:0 - 10 mm

Idizayini yephedi yembobo yokuxhuma:ihlukaniswe yaba izingcezu ezintathu

Ukulungiswa kahle kohlaka lwesikrini:X, Y, θ±5mm

Amandla esisetshenziswa:5.6/ KWH