Uchungechunge lomshini wokuphrinta wesikrini sikasilika

-

Umshini wokufaka uyinki ozenzakalelayo wokulinganisa nokuhlanza

Izici Zobuchwepheshe

I-Adopt PLC control, imodi yokulawula eguquguqukayo nethembekile

Amaqembu amabili ama-roller acindezelayo, iqembu elilodwa noma amabili angakhethwa ukuthi asebenze ngesikhathi esisodwa

Umphumela wokucaba ulungele izidingo ezahlukene

Ukutholwa okuzenzakalelayo kwefilimu ephukile

Ukusebenzisa isikhombimsebenzisi somshini womuntu, kulula ukusebenza

-

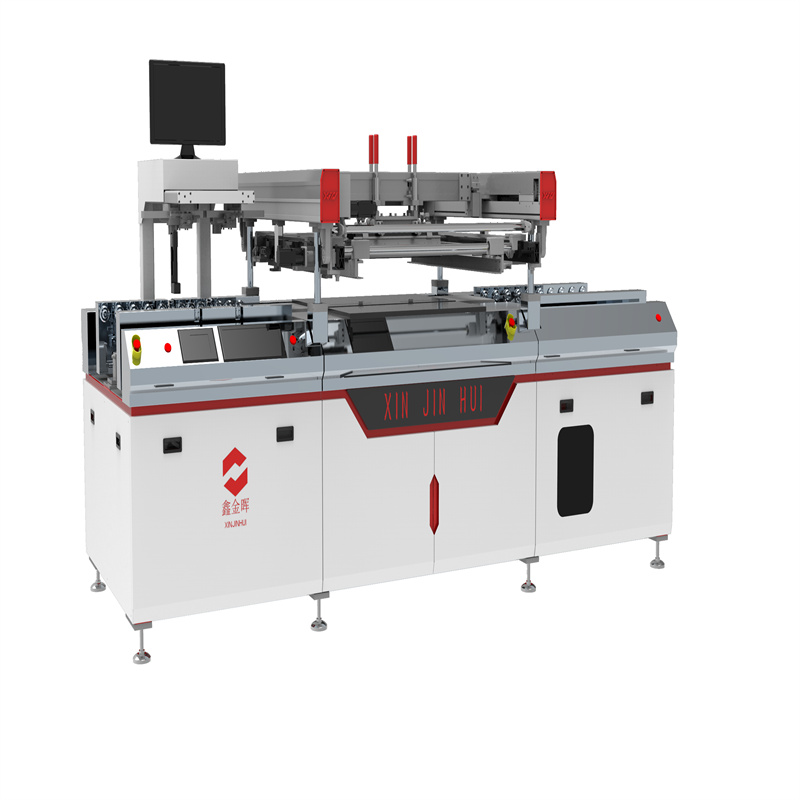

Umshini Wokuphrinta Wesikrini Sethebula Elikabili

Incazelo Yomkhiqizo

Wonke umshini wakhiwe ngamatafula akabili, alungele inqubo yokukhiqiza inki yesekethe/i-solder hole hole, wamukela ukucushwa kwehardware kagesi okwaziwayo ekhaya naphesheya, kufakwe imiqondo yokuklama ethuthukisiwe kanye nezilinganiso zesakhiwo semishini ezinzile, futhi isekelwa inqwaba yobuchwepheshe obunelungelo lobunikazi Ukuqinisekisa ukukhiqizwa nokusebenza kwemikhiqizo okuzinzile nokuthembekile. -

Umshini Wokuphrinta Isikrini esizenzakalelayo

Incazelo Yomkhiqizo

Wonke umshini ulungele inqubo yokukhiqiza inki yokunyathelisa yesekethe/yokuhlanganisa.Yamukela ukucushwa kwe-hardware kagesi okwaziwayo ekhaya naphesheya, ifakwe imiqondo yokuklama ethuthukisiwe kanye nezilinganiso ezinzile zesakhiwo semishini, futhi isekelwa inombolo yobuchwepheshe obunelungelo lobunikazi ukuze kuqinisekiswe ukukhiqizwa nokusebenza komkhiqizo ozinzile nothembekile. -

Umshini wokuphrinta wesikrini sikasilika ohlakaniphile

1,I-Servo motor drives printing kanye ne-pneumatic off screen ukuze ibone ukusebenza kwesikrini okuvumelanayo futhi kuvimbele ngempumelelo ukunamathela kwesikrini.I-servo motor ishayela ucezu lokuphrinta ukuze luhambe ngokushesha nangokushelela ukuze kuqinisekiswe ukuma okunembile kwesiqeshana sokuphrinta.

I-2, i-Servo motor kanye nomhlahlandlela wesitimela onembile uqinisekisa ukuma okunembile nempilo ende yesevisi.Isakhiwo sokuphakamisa esiqondile esivundlile sohlaka lokuphrinta siqinisekisa ukuthi ukucindezela kwe-scraper kuyalingana.

3,i-smart interface touch operation, kulula ukusetha, nokutholwa kwamaphutha okuzenzakalelayo kanye nesibonisi sokuxazulula inkinga.Ingcindezi yokuphrinta kanye nepuleti yesikrini ingalungiswa ngokufanele futhi ngokunembile, futhi i-angle ye-scraper ingalungiswa ngokuthanda.

I-4, uhlelo lokuqondanisa okuzenzakalelayo kwesithombe se-CCD, oluhlanganiswe nezinkundla ezigijima kwesokunxele nesokudla, lunika amandla ukusebenza okusheshayo nokunemba okuphezulu kokuqondanisa.Ukucutshungulwa kwenani eliningi lesistimu yesithombe akunqunyelwe yinoma iyiphi ihluzo, futhi noma yiziphi ihluzo zingasetshenziswa njengethagethi.

-

Umshini Wokufaka I-Semi-Automatic Pressure Plug

Wonke umshini unengxenye yawo yepulaki ye-booster system, elungele imbobo yepulaki ye-viscosity ephezulu.Yamukela ukucushwa kwehadiwe kagesi okwaziwayo, ifakwe imiqondo yokuklama ethuthukisiwe kanye nesilinganiso esizinzile sesakhiwo semishini, futhi isekelwa inombolo yobuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa ukukhiqizwa nokusebenza kwemikhiqizo okuzinzile nokuthembekile.

-

Intelligent Pressure Plug-nge-Screen Printer

Incazelo Yomkhiqizo

Wonke umshini wakhiwe ingxenye ye-CCD ehlakaniphe ngokugcwele,

ingxenye yokuxhuma enesistimu ye-booster, kanye nesigaba sokuhlehla esibonakalayo.Kwesokunxele

kanye nethebula le-shuttle elingakwesokudla lihambisa izingxenye eziphrintiwe kuchungechunge phakathi nendawo.Ingahlangana phezulu

imbobo yepulaki ye-viscosity/resin.