Imikhiqizo

-

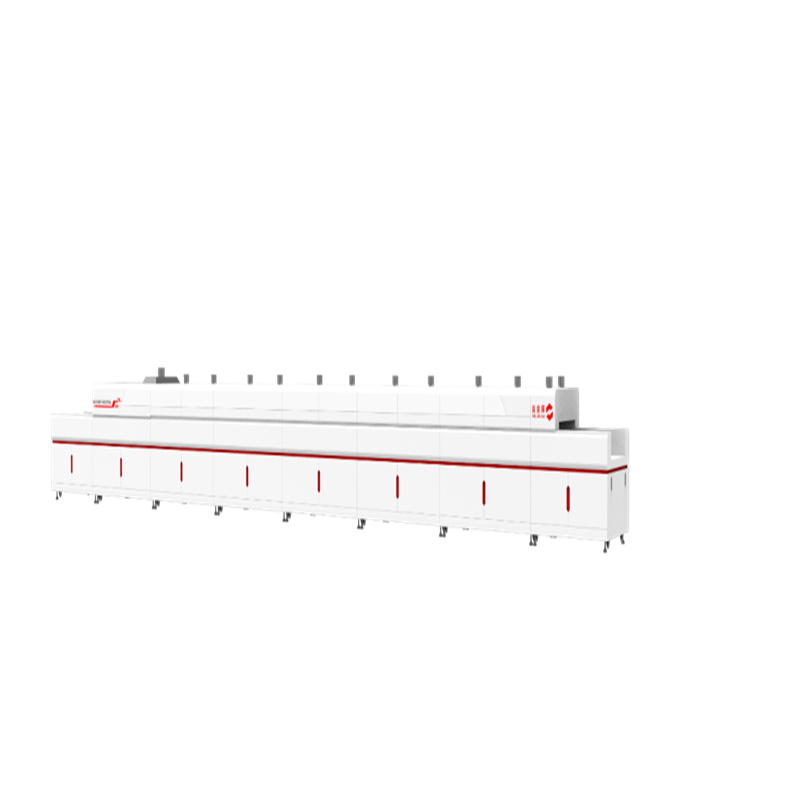

Uhlobo lwe-roller umhubhe wokomisa ihhavini

Incazelo Yomkhiqizo

Amahhavini omhubhe womoya oshisayo ahanjiswa embonini aqukethe izindawo eziningi ezishisisa ngogesi ngazinye, ezingalawulwa ngazodwana ngokwezinga lokushisa.Isibonelo, ama-PCB ayacutshungulwa

hamba kuhhavini futhi unqamule indawo ngayinye ngenani elilawulwayo ngokudluliswa kwe-reel rolling.Ochwepheshe balungisa isivinini sokuthutha kanye namazinga okushisa wendawo ukuze kuzuzwe isikhathi esaziwayo

kanye nephrofayili yezinga lokushisa.Iphrofayili esetshenziswayo ingahluka kuye ngezidingo zama-PCB acutshungulwayo ngaleso sikhathi.

Wonke umshini wakhiwe ingxenye yokuphakela, indawo yokomisa ehambisana nesistimu ekhiqiza amandla okonga amandla enelungelo lobunikazi, isistimu yokudlulisa umoya, isistimu yokulondoloza ukushisa, kanye nesigaba sokuthulula.Yamukela idizayini yokudlulisa i-roller enelungelo lobunikazi engenisiwe, ukusebenza okuzinzile kanye nomthelela omuhle wokonga amandla.Ifanele amabhodi esekethe ngaphambi kokubhaka/ngemuva kokubhaka. -

Ihhavini yokomisa yomhubhe evalekile

Incazelo Yomkhiqizo

Amahhavini ahanjiswa kabusha embonini aqukethe izindawo ezishisisa ngazo zonke ngazinye, ezingalawulwa ngazinye ngokwezinga lokushisa.Impahla yokupakisha ecutshungulwayo ihamba kuhhavini futhi idabule indawo ngayinye ngenani elilawulwayo.Ochwepheshe balungisa isivinini sokuthutha kanye namazinga okushisa wendawo ukuze kuzuzwe isikhathi esaziwayo

kanye nephrofayili yezinga lokushisa.Iphrofayili esetshenziswayo ingahluka kuye ngezidingo zezinto zokupakisha ezicutshungulwa ngaleso sikhathi.

Wonke umshini wakhiwe ingxenye yokuphakela, indawo yokomisa ehambisana nesistimu ekhiqiza amandla okonga amandla enelungelo lobunikazi, isistimu yokushisa yomoya odluliswayo, kanye nesigaba sokuthulula.Ukwamukela idizayini yokudlulisa insimbi eyingqayizivele, ukusebenza okuzinzile nomthelela omuhle wokonga amandla.Ifanele ama-substrates ephakheji yangaphambi kokubhaka/ngemuva kokubhaka. -

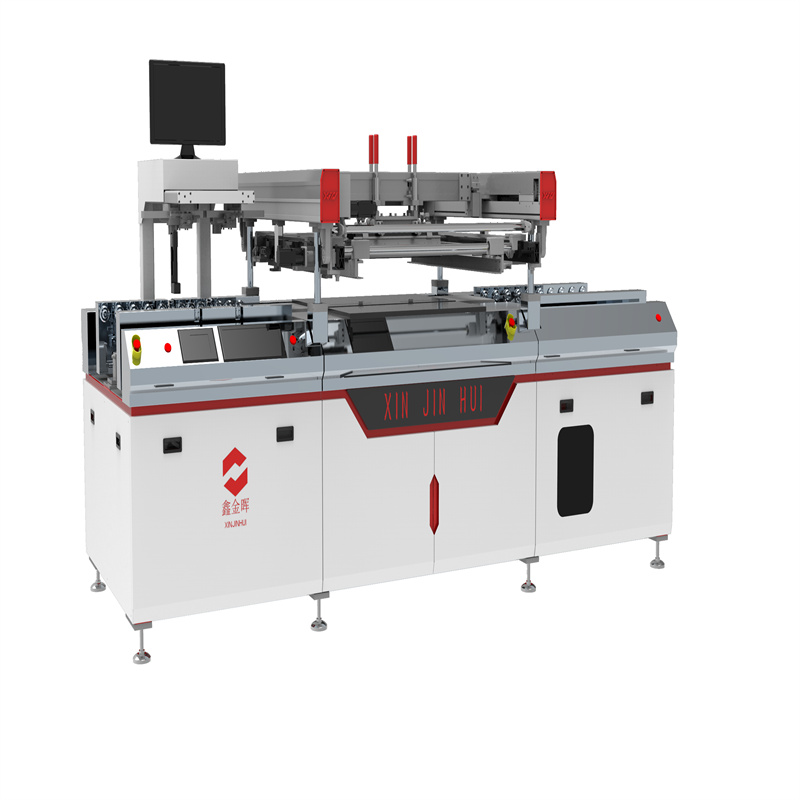

Umshini wokuphrinta wesikrini sikasilika ohlakaniphile

1,I-Servo motor drives printing kanye ne-pneumatic off screen ukuze ibone ukusebenza kwesikrini okuvumelanayo futhi kuvimbele ngempumelelo ukunamathela kwesikrini.I-servo motor ishayela ucezu lokuphrinta ukuze luhambe ngokushesha nangokushelela ukuze kuqinisekiswe ukuma okunembile kwesiqeshana sokuphrinta.

I-2, i-Servo motor kanye nomhlahlandlela wesitimela onembile uqinisekisa ukuma okunembile nempilo ende yesevisi.Isakhiwo sokuphakamisa esiqondile esivundlile sohlaka lokuphrinta siqinisekisa ukuthi ukucindezela kwe-scraper kuyalingana.

3,i-smart interface touch operation, kulula ukusetha, nokutholwa kwamaphutha okuzenzakalelayo kanye nesibonisi sokuxazulula inkinga.Ingcindezi yokuphrinta kanye nepuleti yesikrini ingalungiswa ngokufanele futhi ngokunembile, futhi i-angle ye-scraper ingalungiswa ngokuthanda.

I-4, uhlelo lokuqondanisa okuzenzakalelayo kwesithombe se-CCD, oluhlanganiswe nezinkundla ezigijima kwesokunxele nesokudla, lunika amandla ukusebenza okusheshayo nokunemba okuphezulu kokuqondanisa.Ukucutshungulwa kwenani eliningi lesistimu yesithombe akukhawulelwe yinoma yiziphi ihluzo, futhi noma yiziphi ihluzo zingasetshenziswa njengethagethi.

-

Umshini Wokufaka I-Semi-Automatic Pressure Plug

Wonke umshini unengxenye yawo yepulaki ye-booster system, elungele imbobo yepulaki ye-viscosity ephezulu.Yamukela ukucushwa kwehadiwe kagesi okwaziwayo, ifakwe imiqondo yokuklama ethuthukisiwe kanye nesilinganiso esizinzile sesakhiwo semishini, futhi isekelwa inombolo yobuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa ukukhiqizwa nokusebenza kwemikhiqizo okuzinzile nokuthembekile.

-

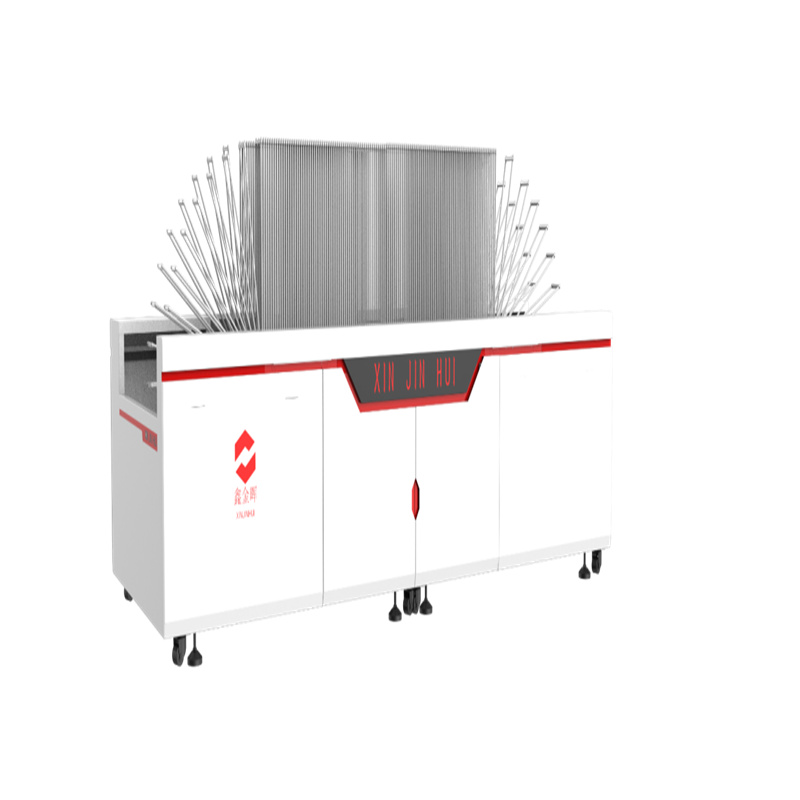

Solar Profile Panel Turnover Buffer

Incazelo Yomkhiqizo

Wonke umshini wakhiwe ingxenye yokulayisha, i-flap yohlobo lwelanga, kanye nengxenye yokukhipha.Ukwamukela idizayini yokudlulisa idiski enelungelo lobunikazi emise okwendandatho, ukusebenza okuzinzile.Ifanele ukuphenduka kwebhodi lesifunda, ukupholisa kanye nokugcinwa kwesikhashana. -

Irejista yokudlulisa evundlile evula ikhasi

Incazelo Yomkhiqizo

Wonke umshini wakhiwe ingxenye yokulayisha, irack yesikhashana yokugcina kanye nesigaba sokuthulula.Ukwamukela idizayini yepuleti lobunikazi bokuzuzwa kobunikazi bokuhambisa, ukusebenza okuzinzile.Ifanele isitoreji sesikhashana samabhodi wesifunda. -

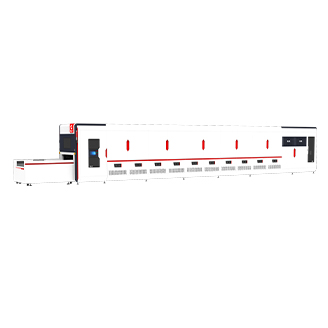

I-Side Clip Conveyor Tunnel Oven

Incazelo Yomkhiqizo

Amahhavini aphinde adluliselwe embonini aqukethe izindawo ezishisisa ngazodwana, ezingalawulwa ngazinye ngezinga lokushisa.Ama-PCB ayacutshungulwa

hamba kuhhavini futhi udabule indawo ngayinye ngenani elilawulwayo.Ochwepheshe balungisa isivinini sokuthutha kanye namazinga okushisa wendawo ukuze kuzuzwe isikhathi esaziwayo

kanye nephrofayili yezinga lokushisa.Iphrofayili esetshenziswayo ingahluka kuye ngezidingo zama-PCB acutshungulwayo ngaleso sikhathi.

Wonke umshini ulayishwa isiteji sokumisa okuzenzakalelayo, futhi indawo yokomisa ifaniswe nesistimu yokushisa yokonga amandla enelungelo lobunikazi, isistimu yokuthutha emoyeni, isistimu yokugcina ukushisa, kanye nokudla okuzenzakalelayo.Yamukela isiqeshana esinelungelo lobunikazi esiyingqayizivele sokubamba uhlangothi, ukusebenza okuzinzile nomthelela omuhle wokonga amandla.Ilungele amabhodi wesifunda wangaphambi kokubhaka./Ngemva kokosa. -

Intelligent Pressure Plug-nge-Screen Printer

Incazelo Yomkhiqizo

Wonke umshini wakhiwe ingxenye ye-CCD ehlakaniphe ngokugcwele,

ingxenye yokuxhuma enesistimu ye-booster, kanye nesigaba sokuhlehla esibonakalayo.Kwesokunxele

kanye nethebula le-shuttle elingakwesokudla lihambisa izingxenye eziphrintiwe kuchungechunge phakathi nendawo.Ingahlangana phezulu

imbobo yepulaki ye-viscosity/resin. -

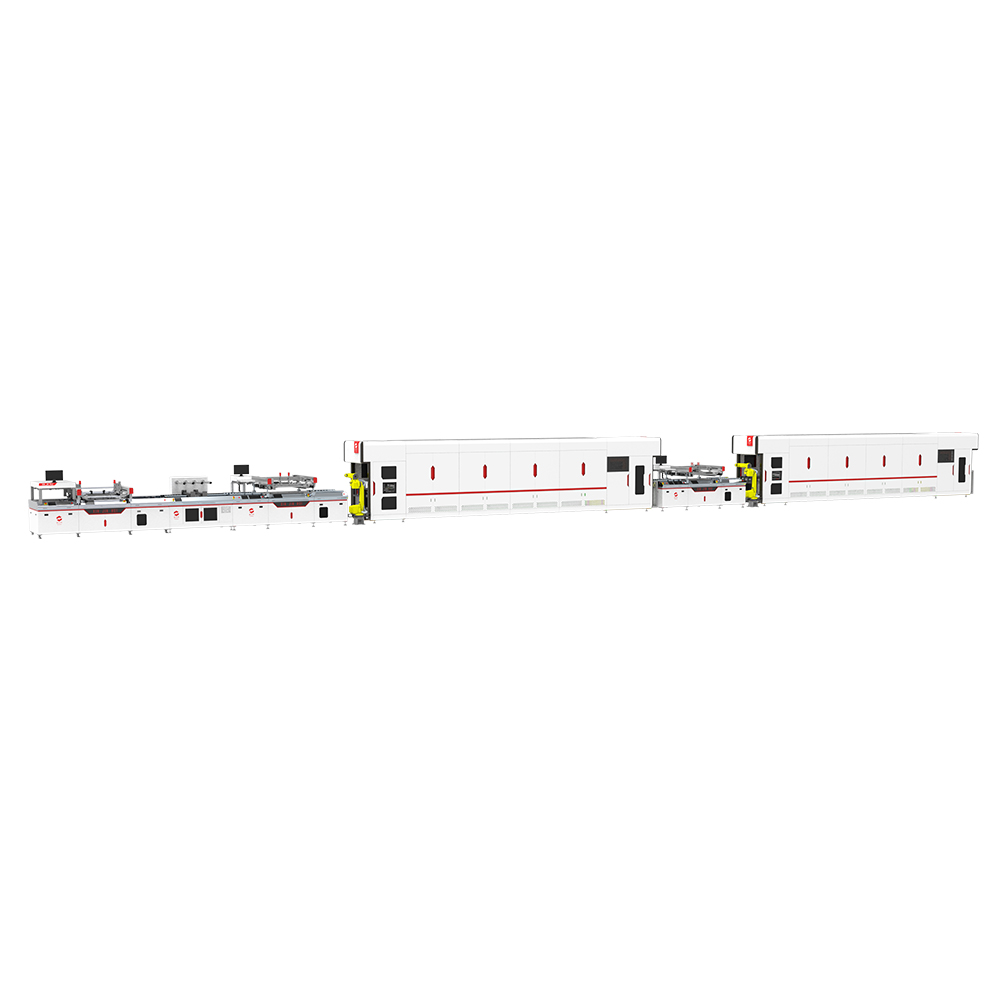

Ngokugcwele Okuzenzakalelayo Solder Mask Three Umshini Qhubeka Ukuphrinta Line

Ukwethula umkhiqizo:Ukucushwa kwezisetshenziswa zolayini wokukhiqiza: ingcindezi ehlakaniphile yokuxhuma-ngomshini → umshini wokulinganisa ozenzakalelayo →Iphrinta yesikrini semaski soda ehlakaniphile → indawo ezenzakalelayo vula →Iphrinta yesikrini semaski soda ohlakaniphile → isiqeshana esiseceleni sehhavini ye-turnel.

Ukuxhuma okuzenzakalelayo okugcwele-ngomugqa wokuphrinta kwemaski ye-solder: kusebenza kunqubo yokuphrinta yesikrini semaski ye-PCB ye-solder ye-multilayer panel, amabhodi esekethe amancane / awugqinsi.Yamukela ukucushwa kwehadiwe kagesi okwaziwayo, iphethe imiqondo yokuklama ethuthukisiwe, ukwakheka komshini ozinzile, futhi isekelwa inombolo yobuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa ukukhiqizwa nokusebenza kwemikhiqizo okuzinzile nokuthembekile. -

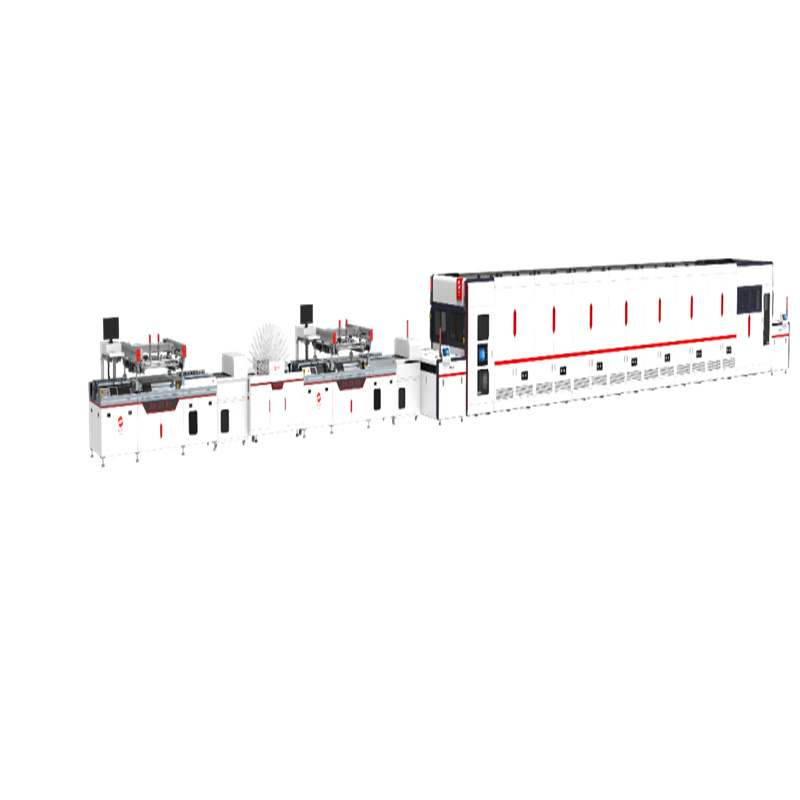

Ulayini Wokuphrinta Wemaski Wokuzenzela Okuzenzakalelayo Okuzenzakalelayo

Ukwethula umkhiqizo: Ukucushwa kwezisetshenziswa zolayini wokukhiqiza: umshini ohlakaniphile wokuxhuma ngomshini → umshini wokulinganisa ozenzakalelayo →Iphrinta yesikrini semaski ye-solder ehlakaniphile → ihhavini lokuhambisa elimisiwe →Iphrinta yesikrini semaski ye-solder ehlakaniphile → ihhavini yokuthutha emisiwe

Umugqa wokukhiqiza imaski wepuleti elincanyana othomathikhi eliphelele: uyasebenza enqubweni yokukhiqiza eyinki ye-mask ye-solder yezinombolo zezinto ezibonakalayo, amabhodi amancane / awugqinsi.Yamukela ukucushwa kwe-hardware kagesi okwaziwayo ekhaya naphesheya, iphethe imiqondo yokuklama ethuthukisiwe, ukwakheka komshini ozinzile, futhi isekelwa inombolo yobuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa ukukhiqizwa nokusebenza kwemikhiqizo okuzinzile nokuthembekile. -

Umugqa Wokuphrinta Wesikrini Wezinganekwane ze-PCB ezizenzakalelayo

Ukwethula umkhiqizo:Ukucushwa kwezisetshenziswa zolayini wokukhiqiza: Umshini wokuphrinta wesikrini okhaliphile → umshini we-uv →Umshini wokuphehla umumo welanga → Iphrinta yesikrini engu-B ehlakaniphile → i-oven ye-wicket conveyor turnnel.Lo mshini wakhiwe ngokuxhuma imishini eminingi ukuze kuzuzwe ukusebenza kahle kokukhiqiza okuzenzakalelayo;,hhayi kuphela inciphisa izindleko zabasebenzi, kodwa futhi ifinyelela umgomo wokonga amandla kanye nokunciphisa i-carbon (kusukela ekunyatheliseni kwamaphasi amabili okuqala nokubhaka kabili kuya kokunyathelisa kwamaphasi amabili kanye nokubhaka okukodwa).

Umugqa wokuphrinta wesikrini ophelele wezinganekwane ze-PCB: uyasebenza enqubweni yokukhiqiza yokuphrinta isikrini sezinganekwane ze-PCB sephaneli yezendlalelo eziningi, amabhodi wesekethe azacile / awugqinsi.Yamukela ukucushwa kwehadiwe kagesi okwaziwayo, iphethe imiqondo yokuklama ethuthukisiwe, ukwakheka komshini ozinzile, futhi isekelwa inombolo yobuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa ukukhiqizwa nokusebenza kwemikhiqizo okuzinzile nokuthembekile.