Enqubweni yokukhiqiza okuzenzakalelayo kwamabhodi e-PCB namabhodi e-SMT, ukugeleza kwenqubo kunzima futhi kuyinkimbinkimbi.Kubaluleke kakhulu ukugcina ukukhiqiza kushelela, okulingana nokwenza ngcono ukusebenza kahle nokunciphisa izindleko.Ngenxa yalesi sizathu, uchungechunge lwamabhodi e-SMT, amabhodi esekethe e-PCB, kanye nemishini ehlakaniphile eyisekela ngokugcwele iye yatholwa ukuze kuxazululwe inkinga.Phakathi nenqubo yokukhiqiza, kuba nezinkinga ezifana nokuminyana kwempahla kanye nokushoda, nokungaqini kwesandla nokungasheleli.Kulolu shicilelo, sikulethela umshini we-pcb static ovundlile wokupholisa ophakamisa isitoreji sesikhashana, ochaza isimiso sokusebenza kanye nomsebenzi wesizukulwane esisha semishini yokugcina yesikhashana ye-pcb, kanye nesixazululo esisodwa-stop sesekethe ye-PCB yokubhafa kwebhodi, ukupholisa, ukuthuthwa kweshidi nokunye. izidingo ezidingekayo zezinqubo eziningi efekthri yebhodi.

1. Iqhaza lebhodi le-SMT kanye nebhodi le-PCB lemishini yesikhashana yokugcina inqolobane yesikhashana

Ibhodi le-SMT kanye nebhodi le-PCB ibhodi le-cache ezenzakalelayo nemishini yokugcina yesikhashana ingadlala indima yokudlulisa, ukugcina ibhafa, ukupholisa, nokuthuthwa kwamapuleti ngenqubo ngayinye yokukhiqiza ngesikhathi sokukhiqizwa okuzenzakalelayo kwamabhodi esekethe e-PCB.Ngokusebenzisa inqolobane ezenzakalelayo kanye nemishini yokugcina yesikhashana, Lungiselela ngokuphumelelayo izinyathelo zenqubo ngokuncika okuphansi kwabasebenzi, londoloza izindleko zabasebenzi, unciphise isikhathi sokulinda, uqinisekise isigqi sokukhiqiza esibushelelezi nesilawulekayo, ugweme ngokuphumelelayo ukuminyana kokukhiqiza, gwema ukuqina kokukhiqiza ngenxa yokushoda kwezinto ezibonakalayo nezinye izinkinga, kanye nezinkinga ezibangelwa ukucubungula okungazelelwe kwe-Phenomena njengokushayisana kwepuleti kanye nokulimala kungaqinisekisa ukusebenza okuzinzile nokuthembekile ngenkathi kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza.

2. Ibhodi le-SMT/PCB ibhodi le-cache ezenzakalelayo yezindawo zobuhlungu besikhashana kanye nobubi bemishini yendabuko

1. Esikhathini esidlule, amabhodi e-SMT namabhodi e-PCB awazange asebenzise imishini ye-cache ezenzakalelayo, ikakhulukazi ngenxa yokuthi ayekhathazekile ngokuthi izinto zokusebenza zizoklwejwa futhi ziklwejwe endaweni yebhodi ngesikhathi sokusebenza, okubangela ukuhlehla nokushayisana.

2. Imishini evamile yokugcina inqolobane emakethe inemikhawulo ethile, efana: nenani elinganele lesikhashana lesitoreji nesikhathi sokuphumula, usayizi wemishini emikhulu, kanye ne-automation yezintambo engalungile.Okwesibili, ukwakheka kwemodi yokusebenza akufanelekile ngokwanele, okubangela ukuthi amaphaneli athuthwe ngesikhathi senqubo yokuthutha.Izinkinga ezifana nokugoqa zingase zenzeke, ezithinta ikhwalithi yomkhiqizo.Kwamanye amabhodi wesekethe we-PCB anosayizi omkhulu nesisindo esisindayo, izingxenye ezifana namagiya okuqondisa zingase zisindwe, zithinte impilo yezinto zokusebenza futhi kubangele izindleko eziphezulu.

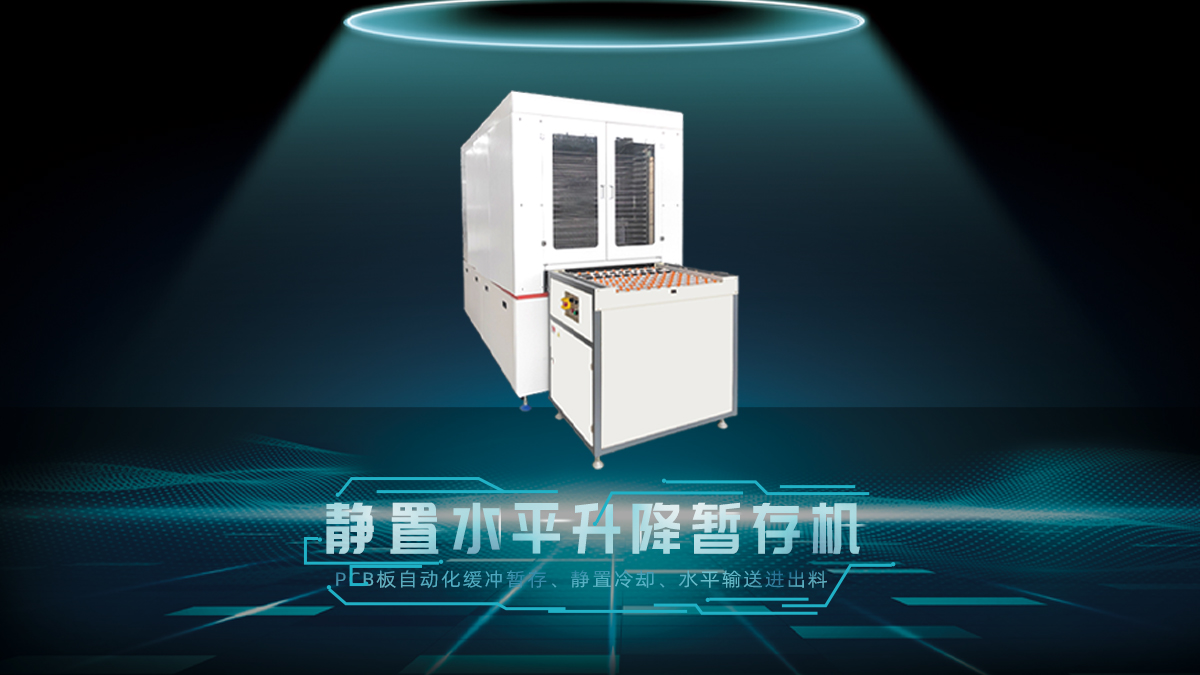

3. Umgomo wokusebenza kanye nokwethulwa kwesizukulwane esisha senqolobane ezenzakalelayo ngokuphelele kanye nomshini wokugcina wesikhashana - ukuphakamisa okuvundlile okumile kanye nokupholisa umshini wokugcina wesikhashana

Njengomkhiqizi ochwepheshe wemishini ezishintshayo ezihlakaniphile embonini ye-PCB iminyaka engu-20, isizukulwane esisha sika-Xin Jinhui somshini wokupholisa ovundlile omile wokupholisa wesikhashana sisekelwe enanini elikhulu lesipiliyoni sokubambisana kwekhasimende lebhodi lesifunda le-PCB kanye nempendulo yesidingo samakhasimende, ngokombono we-PCB. Inqubo yekhasimende lebhodi lesifunda, Kuyidivayisi ye-PCB yenqolobane yenqolobane eklanywe umhlaba wonke futhi ngokusungula izinto ezintsha.Ixazulula ngobuhlakani ukushiyeka kwemishini yenqolobane yendabuko, futhi ingenza ngokwezifiso inani lezendlalelo futhi isethe isikhathi sokulinda ngokuya ngesimo sangempela sekhasimende.

Umehluko oyinhloko phakathi komshini wokupholisa ovundlile omile ovundlile kanye nomshini wesigcinalwazi senqolobane yendabuko ukuthi ibhodi le-PCB lihanjiswa ngokushelela endaweni evundlile, nohlangothi olungenayo no-A oluphumayo, ngaphandle kwesidingo sokuphendula ibhodi ukuze ugweme ukuthintana. phakathi kwamabhodi wesifunda, ngaleyo ndlela kuvimbela Uchungechunge lwamakhasimende lukhathazekile ngezinkinga ezingenzeka, kodwa asikho isidingo sokukhathazeka ngamabhodi wesifunda amancane.Yonke inqubo ibekwe ngokuvundlile futhi ngeke igoqe ngenxa yokungalingani.

Ifomu lokuklama elisekelwe ku-cyclic lift-type isitoreji sesikhashana lenza wonke umshini uminyene futhi ube nengqondo, alichithi isikhala eseqile, lihlanganisa indawo encane, linenani eliphakeme lesikhashana lokugcina nesikhathi sokuphumula, futhi linokusebenza ngempumelelo kwezindleko okuphezulu kakhulu. , futhi ifaneleka kakhulu ukufakwa kwebhodi le-SMT/PCB ngesilinganiso esigcwele.Ukukhiqizwa komugqa okuzenzakalelayo.

Ehlanganiswe neminye imiklamo eningiliziwe ehlakaniphile, amaphaneli angavikelwa ngangokunokwenzeka ngesikhathi sokusebenza komshini wokugcina wokupholisa ophakamisayo omile ovundlile, njengokuthi:

1. I-roller ye-conveyor isebenzisa i-motor elawula isivinini + i-conveyor yebhande + i-silicone roller, enomthelela wokuvimbela umsindo ovela ekungqubuzaneni phakathi kwebhodi lesifunda kanye nenduku yokusekela, futhi ngesikhathi esifanayo ivimbela ibhodi lesifunda ukuthi lingangeni. ukulinyazwa.

2. Ibhande lokufaka i-conveyor kanye nebhande lokuhambisa lithatha ama-pallet racks aqinisiwe, anokwesekwa okuqinile namandla okuthwala okuqinile futhi angakwazi ukuzivumelanisa nezimo ezihlukahlukene zepuleti.

3. Isikulufu sokuhumusha sithatha i-fiber rod yengilazi embozwe ngendandatho encane ye-silicon, ekwazi ukumelana nezinga lokushisa eliphezulu futhi ingavimbela ukushelela kwebhodi lesifunda kanye nokuhlehlisa.

Umshini omile wokupholisa ovundlile wokupholisa wesikhashana ungasetshenziswa kabanzi ezinqubweni zebhodi lesifunda se-PCB futhi unokuguquguquka okuqinile, okufana: umsebenzi wokupholisa omile ngaphambi nangemva kokuchayeka, umsebenzi wokulungisa ibhodi likawoyela omhlophe nokushelela, futhi ungahlangabezana nezidingo ezikhethekile. amabhodi ngemuva kokubhaka kwangaphambili.Umsebenzi wokubhaka nokupholisa, njll.

Lokhu okungenhla kwethula isimiso sokusebenza kanye nomsebenzi womshini ka-Xin Jinhui osanda kwethulwa omile ovundlile wokupholisa isivande, futhi kuhlaziya ngokuningiliziwe izidingo nokukhathazeka kokugcinwa kwesiphakeli, ukupholisa okungashintshi, nokuthuthwa kwamapuleti ohlelweni lokukhiqiza oluzenzakalelayo lwamakhasimende ebhodi le-PCB.ukukhathazeka, nokuxazulula ukushiyeka kwemishini yesikhashana yokugcina isikhashana, inikeze ukwesekwa okuqinile kokunye ukweqa ezingeni le-automation yabakhiqizi bebhodi le-PCB, ukunciphisa izidingo zabasebenzi kanye nezindleko zabasebenzi, kuqinisekiswe ukusebenza okuzenzakalelayo ngokugcwele, okunembile, okuphumelelayo nokuzinzile, futhi kufinyeze ukukhiqizwa kokulinda noma ukuqina. isikhathi.Gwema umthelela wezinto ezingazinzile njengamaphutha okwenziwa ngesandla, unciphise udoti wokukhiqiza, futhi unikeze ukudlala okuphelele kunani lokuzenzakalelayo.Ngaphezu kwalokho, i-Xinjinhui inganikeza nombhalo/, ingcindezi noma imishini yokuxhuma eyinki ye-vacuum resin, kanye ne-solder mask pre-baking ngokwezidingo zamakhasimende./ Ukubhala umbhalo ngemva kokubhaka, ihhavini ye-infrared tonnel kanye noxhumano lokukhiqiza konke-in-one izinsizakalo zokwenza ngokwezifiso ezingajwayelekile zixazulula ngokugcwele amaphuzu obuhlungu nobunzima bamakhasimende, zinikeza ukudlala okuphelele endimeni yezixazululo zemishini, futhi zikhiqize izinzuzo ezingaphezu kwalokho obekulindelwe.

Isikhathi sokuthumela: Apr-23-2024