Inqubo yemaski yebhodi lesifunda ye-PCB ingenye yezixhumanisi ezibalulekile enqubweni yokukhiqiza ye-PCB, futhi izindaba zayo zekhwalithi zinomthelela obalulekile ekusebenzeni nasekuthembekeni kwe-PCB.Enqubweni ye-mask ye-solder, izinkinga zekhwalithi ezivamile zihlanganisa ama-pores, i-solder yamanga, nokuvuza.Lezi zinkinga zingase zingaholeli kuphela ekunciphiseni ukusebenza kwe-PCB nokwethembeka, kodwa zingase zilethe nokulahlekelwa okungadingekile ekukhiqizeni.Lesi sihloko sizokwethula izindlela ezisebenzayo zokuxazulula lezi zinkinga futhi sihlole ukusetshenziswa kwemishini yokunyathelisa yesikrini semaski ye-PCB solder ekuxazululeni lezi zinkinga.

1. Incazelo yezinkinga ezijwayelekile zekhwalithi kunqubo yemaski ye-solder ye-PCB

1. Stomata

I-Porosity ingenye yezinkinga ezijwayelekile zekhwalithi kunqubo ye-PCB solder mask.Ngokuyinhloko kubangelwa ukukhathala okunganele kwegesi ku-solder mask material.Lezi zimbotshana zizodala izinkinga ezifana nokusebenza kabi kukagesi namasekethe amafushane ku-PCB ngesikhathi sokucubungula nokusetshenziswa okulandelayo.

2. I-solder ebonakalayo

I-Welding isho ukuthintana okungalungile phakathi kwamaphedi e-PCB nezingxenye, okuholela ekusebenzeni kukagesi okungazinzile kanye nokujikeleza okufushane okulula noma isekethe evulekile.I-soldering ebonakalayo ibangelwa ikakhulukazi ukunamathela okunganele phakathi kwempahla ye-solder mask kanye nephedi noma imingcele yenqubo engalungile.

3. Ukuvuza

Ukuvuza yilapho kukhona ukuvuza kwamanje phakathi kwamasekhethi ahlukene ku-PCB noma phakathi kwesekhethi nengxenye esekelwe phansi.Ukuvuza ngeke kuthinte ukusebenza kwesekethe kuphela, kodwa kungase kubangele nezinkinga zokuphepha.Izizathu zokuvuza zingabandakanya izinkinga zekhwalithi ngempahla ye-solder mask, imingcele yenqubo engalungile, njll.

2. Isixazululo

Ukubhekana nezinkinga zekhwalithi ezingenhla, izixazululo ezilandelayo zingathathwa:

Ngenkinga yama-pores, inqubo yokumboza ye-solder resist material ingenziwa elungiselelwe ukuze kuqinisekiswe ukuthi impahla ingena ngokugcwele phakathi kwemigqa, futhi inqubo yokubhaka yangaphambi kokubhaka ingafakwa ukuze kukhishwe ngokugcwele igesi ku-solder resist material.Ngaphezu kwalokho, ungakwazi futhi ukwengeza ukulungiswa kwengcindezi ye-scraper ngemva kokuphrinta kwesikrini ukuze usize ukuqeda ama-pores.Lapha sincoma ukuthi ufunde ngomshini wokuxhuma imbobo yembobo ye-solder ehlakaniphile onohlelo lwawo lokucindezela.Nge-6 ~ 8 kg yegesi, ingafinyelela I-scraper ingagcwalisa umgodi nge-stroke eyodwa futhi ikhiphe ngokugcwele igesi.Asikho isidingo sokusebenza kabusha imbobo yepulaki ngokuphindaphindiwe.Isebenza kahle, yonga isikhathi nezinkinga, futhi inciphisa kakhulu izinga le-scrap.

Ngenkinga ye-solder ye-virtual, inqubo ingenziwa kahle ukuze kuqinisekiswe ukunamathela okwanele phakathi kwezinto ezibonakalayo ze-solder mask kanye nephedi.Ngesikhathi esifanayo, ngokwemigomo yenqubo, izinga lokushisa lokubhaka kanye nokucindezela kungandiswa ngokufanele ukuze kuthuthukiswe ukunamathela phakathi kwezinto zokumelana ne-solder kanye ne-pad.

Ngezinkinga zokuvuza, ukulawulwa kwekhwalithi yezinto zokumelana ne-solder kungaqiniswa ukuze kuqinisekiswe ukusebenza kukagesi okuzinzile.Ngesikhathi esifanayo, ngokwemigomo yenqubo, izinga lokushisa lokubhaka kanye nesikhathi kungandiswa ngokufanele ukuze kuqiniswe ngokugcwele izinto zokumelana ne-solder, ngaleyo ndlela kuthuthukiswe ukusebenza kokufakwa kwesifunda.

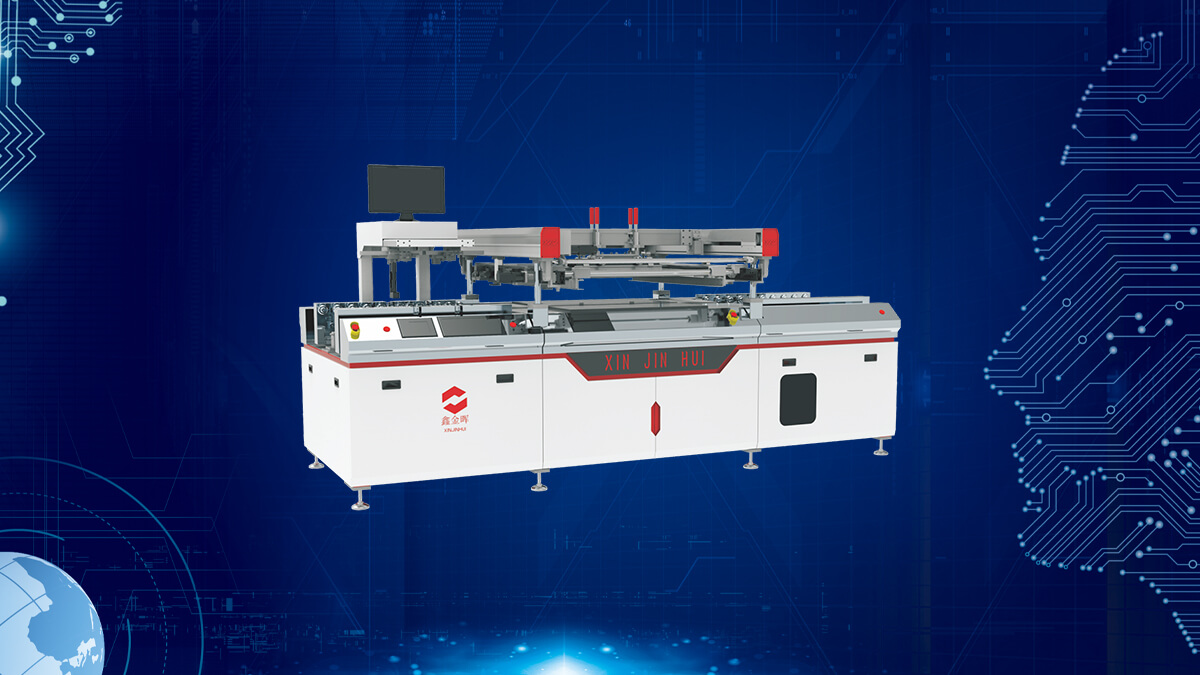

3. Ukusetshenziswa komshini wokuphrinta wemaski we-Xinjinhui PCB wesifunda sebhodi le-solder

Ekuphenduleni izinkinga zekhwalithi engenhla, imaski ye-solder ye-Xinjinhui PCB inganikeza izixazululo eziphumelelayo.Imishini yamukela ubuchwepheshe bokuphrinta kwesikrini esithuthukisiwe, obungakwazi ukulawula ngokunembile inani le-coating kanye nokuma kwempahla ye-solder mask, ukugwema ngokuphumelelayo ukuvela kwama-pores kanye ne-solder yamanga.Ngesikhathi esifanayo, imishini iphinde ibe nomsebenzi wokulawula inqubo ohlakaniphile, ongashintsha ngokushesha izinombolo zezinto ezibonakalayo emizuzwini emi-3 kuya kwemi-5 ngaphandle kwesidingo sokulungiswa kwesondo lesandla futhi ihlanganise uhlelo lokuqondanisa oluhlakaniphe ngokugcwele ukuze kuqinisekiswe ukuthi ukuphrinta kwesikrini semaski solder kunembile futhi kusebenza kahle. .

Ukuzijwayeza kufakazele ukuthi ukusetshenziswa komshini wokunyathelisa we-Xinjinhui PCB webhodi lebhodi le-solder mask screen kungathuthukisa ngempumelelo ikhwalithi nokusebenza kahle kokukhiqiza kwenqubo ye-PCB solder mask.Ukusetshenziswa kwalo mshini akukwazi nje ukunciphisa ukukhiqizwa kwemikhiqizo enesici futhi kuthuthukise ukusebenza kahle kokukhiqiza, kodwa futhi kunikeze amakhasimende imikhiqizo ye-PCB yekhwalithi ephezulu ukuze ahlangabezane nezidingo ezihlukahlukene zohlelo lokusebenza.

4. Isifinyezo

Lesi sihloko sethula izinkinga ezivamile zekhwalithi kanye nezixazululo kunqubo ye-mask solder ye-PCB, igxile ekusetshenzisweni kwe-Xinjinhui PCB yebhodi lesifunda solder imaski yomshini wokunyathelisa isikrini ekuxazululeni lezi zinkinga.Ukuzijwayeza kubonise ukuthi ukusetshenziswa kwe-solder resist kungathuthukisa ngempumelelo ikhwalithi nokusebenza kahle kokukhiqiza kwe-PCB solder inqubo yokumelana, ukunciphisa ukuvela kwemikhiqizo enesici, futhi kuthuthukise ukusebenza kahle kokukhiqiza.Ngesikhathi esifanayo, le mishini inganikeza amakhasimende ngemikhiqizo yekhwalithi ephezulu ye-PCB ukuhlangabezana nezidingo ezihlukahlukene zohlelo lokusebenza.Izixazululo nezindlela ezichazwe ngu-Xin Jinhui kulesi sihloko zinganikeza ireferensi ethile kanye nesiqondiso kumabhizinisi afanelekile.

Isikhathi sokuthumela: Mar-20-2024