Ikhwalithi nokusebenza kwamabhodi esekethe e-PCB kudlala indima ewujuqu kuyo yonke imboni yemikhiqizo ye-elekthronikhi.Inqubo ye-mask efanayo ye-solder nayo iwumugqa obalulekile wokuzivikela wekhwalithi yebhodi lesifunda.Izinga lobuchwepheshe bokuphrinta kwesikrini semaski sabakhiqizi be-PCB kanye nemishini kuzoba nomthelela omkhulu kukhwalithi yamabhodi e-PCB.Kunomthelela omkhulu ekusebenzeni kahle kokukhiqiza kanye nezinzuzo eziphelele zefekthri.Lesi sihloko sisebenzisa isipiliyoni seminyaka engama-20 kubuchwepheshe bebhodi lesifunda le-PCB lombhalo/izinto zokusebenza ukwethula kini amathiphu ayi-10 mayelana nokusebenza kwenqubo nokugcinwa kwemishini yokunyathelisa yesikrini semaski ye-PCB yebhodi le-solder!

1. Ithiphu 1

Kunolwazi oluningi ekukhethweni kwe-screen mesh.Ngezidingo ezihlukene zokuphrinta, udinga ukusebenzisa i-mesh yesikrini efanele ukuze uthole umphumela wokuphrinta olindelekile.Nakuba i-mesh encane, imininingwane ephrintiwe izoba ifaneleka kakhulu, kodwa akusho ukuthi i-mesh encane, ingcono.Okungcono, kuncike kakhulu ekunembeni kwemishini kanye nezidingo zokuphrinta zomshini wokuphrinta wesikrini semaski we-PCB board solder.

2. Ithiphu 2

Ukushuba kwesikrini kuvame ukumaphakathi, ngoba uma ukushubaza kukuncane, isikrini sizocindezelwa phakathi nenqubo futhi siyaxega, okuholela ekucaceni kokuphrinta okwanele.Ngokuphambene nalokho, uma ukungezwani kuphezulu kakhulu, isikrini singahle siphuke futhi silimale., ngakho-ke ukulungiswa kokuqina kwesikrini nakho kuhlola umuzwa wephrinta yesikrini.

3. Ithiphu 3

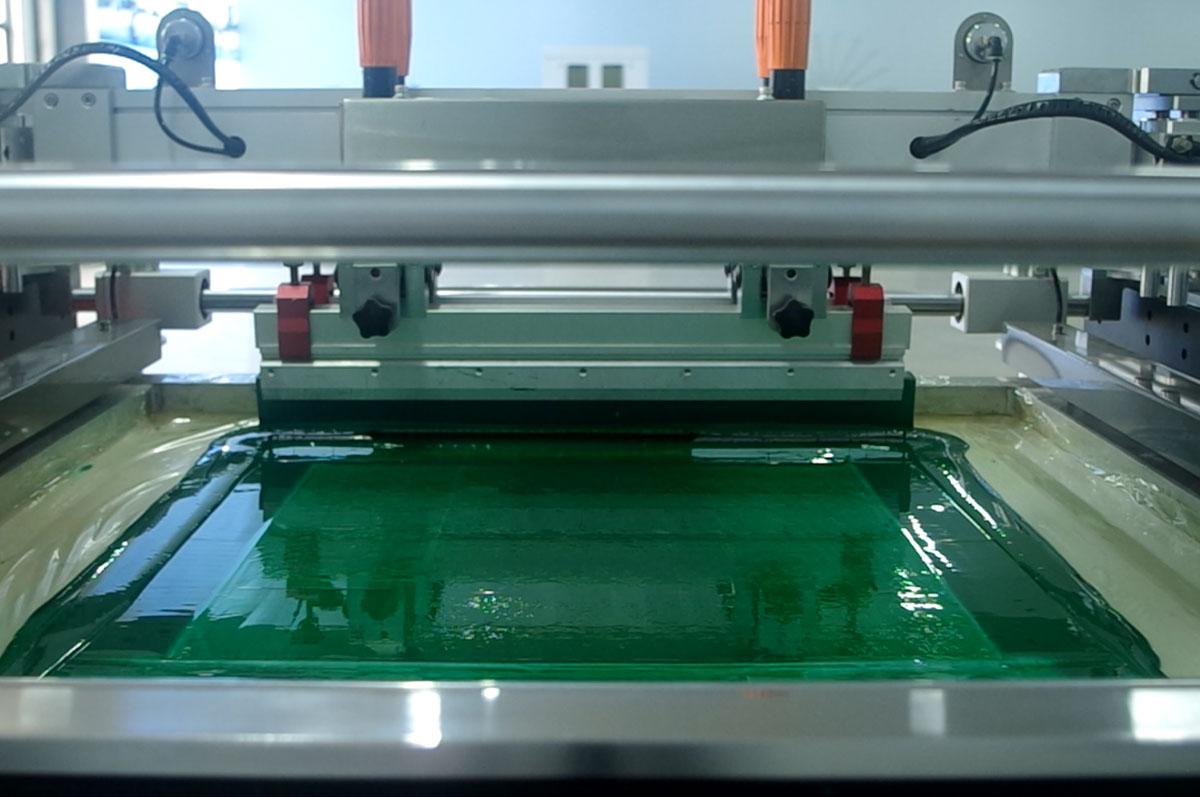

Isikrini kufanele sihlanzwe futhi sishintshwe.Ngemuva kokuphrinta isikrini isikhathi eside, uyinki uzohlala futhi uvimbe isikrini, okuholela emikhiqizweni enesici.Ngakho-ke, ukuhlolwa nokulungiswa kwamaphutha kufanele kwenziwe ngaphambi nangemva kwayo yonke imikhiqizo ukuze kugwenywe ukuthikameza ikhwalithi yokuphrinta futhi kubangele ukulahleka nokumosha.

4. Ithiphu 4

Ifilimu yokuphrinta kufanele icace futhi ihlanzeke, futhi kufanele ihlolwe ukuthi ayinamaphutha noma imihuzuko.Ngaphambi kokusetshenziswa, i-adhesive photosensitive kufanele isetshenziswe lapho kunesidingo ukuze kuqinisekiswe ngempumelelo ukucaca kwesithombe.

5. Ithiphu 5

Ukusethwa kwamapharamitha wokuphrinta kuzothinta ngqo umphumela wokuphrinta, ngakho ukuhlolwa komshini wangaphambi kokukhiqiza kubaluleke kakhulu.Ingcindezi yokuphrinta, isikhathi kanye nesivinini kudinga ukulungiswa kumingcele efanele ukuphrinta umkhiqizo wamanje, ngaleyo ndlela kuthuthukiswe ngempumelelo ikhwalithi, ukusebenza kahle kanye nokuzinza kokunyathelisa.Zama ukugwema ukuhlelwa kabusha kwebhodi lokuchitha kanye nezinye izinto ngangokunokwenzeka.Njengoba kunamamodeli amaningi e-PCB, kuwukuchitha isikhathi okukhulu ukushintsha ukukhiqizwa nokulungisa umshini ngaso sonke isikhathi.Iphinde ithembele ekuhlangenwe nakho nobuchwepheshe bephrinta yesikrini se-mask solder, ngakho-ke izinga elihlakaniphile lephrinta yesikrini se-mask solder , isivinini sokushintsha imodeli kanye noshintsho lokukhiqiza kubaluleke kakhulu, okuthinta kakhulu ukusebenza kahle kokukhiqiza jikelele.

6. Ithiphu 6

Uyinki ungenye yezinto ezibalulekile kukhwalithi yokuphrinta isikrini semaski ye-solder.Ngakho-ke, inki kufanele ikhethwe kumaski ozinikele ukuze kuqinisekiswe umphumela wokuphrinta isikrini.Okwesibili, umbala kanye nonyaka kayinki kufanele kukhethwe ngokuvumelana nezidingo ze-solder mask.

7. Ithiphu 7

Ukuze uvimbele izinkinga ezinjengokuqiniswa kwe-inki, uyinki kufanele ushukunyiswe njalo ukuze uyigcine isesimweni esizinzile, ngaleyo ndlela kugwenywe ukuvaleka kwemeshi phakathi nenqubo yokuphrinta.

8. Ithiphu 8

Gada izinga lokushisa kanye nomswakama wendawo ezungezile.Ngenxa yokuthi izinga lokushisa nomswakama kunomthelela othize ku-fluidity kanye nokunamathela kukayinki, kufanele sibe yinkosi yamapharamitha wendawo yokukhiqiza futhi silungise ngokufanele ukuze sigweme imiphumela engadingekile kukhwalithi yokuphrinta kwesikrini.

9. Ithiphu 9

Funda kokuhlangenwe nakho kokuphrinta kwesikrini semaski yebhodi le-PCB, finyeza idatha nezindlela namasu, thola izixhumanisi ezithinta ukusebenza kahle nekhwalithi yokuphrinta, futhi uthuthukise ukugeleza kwenqubo, ngaleyo ndlela ulethe izinzuzo kubakhiqizi be-PCB.

10. Amathiphu 10

Akukho lutho olungcono kunokweqiwa.Kufanele sinake ukuhlolwa kwekhwalithi yesinyathelo ngasinye sokukhiqiza ukuze sigweme ukulahlekelwa okukhulu ngenxa yokugada okuncane.Zithole kusenesikhathi ukuze unciphise umthelela.

Ngokulandela amathiphu ayi-10 owethulwe ngu-Xin Jinhui ngenhla, uzokwazi ukuqedela inqubo yokuphrinta isikrini semaski ye-PCB yebhodi lesifunda kangcono nangokushelela, ngaleyo ndlela uthuthukise ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo, ugweme ukulahlekelwa nokumosha okungadingekile, futhi ukhuthaze ngempumelelo izinzuzo ezibanzi. .ngcono.Ngithemba ukuthi isingeniso esingenhla singasiza inkampani yakho ekusebenzeni, ekusetshenzisweni nasekugcinweni kwemishini yokunyathelisa yesikrini semaski ye-PCB yesifunda se-PCB kanye nenqubo yokukhiqiza!

Isikhathi sokuthumela: Mar-06-2024